Understanding Powder Coating and Its Application Process

What Is Powder Coating: Powder coating is an interesting way of protecting and decorating metal and other items. It is used heavily on buildings, furniture, auto components, fences, equipment, and anything metallic that is outdoors or subject to tough conditions.

Powder coating does not use wet paint like regular paint. Instead, dry powder is used. The powder is attracted to the surface using electricity and then gets hot to form a smooth, hard finish. It protects the surface from rust, scratching, denting, and the sun’s damage, and also gives the surface a clean, colorful appearance.

Why Do We Use Powder Coating?

Metal may rust or deteriorate over time, especially when it gets wetted by rain, sunlight, or salt (like on the roads or at the beach). Powder coating gives the metal a strong outer layer that protects it. Even heavy metals such as stainless steel will rust if it is left unprotected. Powder coating offers a second coating of protection.

It is also used on non-metal items like plastic, wood, MDF, and fiber to cover them from the environment and enhance their appearance.

How Powder Coating Works

Powder coating comes in three forms, and each works by coating the surface with powder and then hardening it:

- Thermoset – most used and cheapest.

- Thermoplastic – more durable and elastic but more expensive.

- UV Curable – best for things that can’t withstand too much heat, like plastic or wood.

Types of Powder Coating

- Thermoset

- Cost-effective and easy to apply

- Great for everyday use

- It can’t be remelted once it has been heated and hardened

- Thermoplastic

- Stronger and more flexible as well

- It can be remelted and re-used again

- Thicker and best for parts that could be struck or bent

- UV Curable

- Processed with UV light and not only heat

- Great for heat-sensitive materials

- Saves energy and time

- The Powder Coating Process

Powder coating is done in three simple steps:

- Preparation

You have to clean the surface really well. Any grease, oil, or rust will make the powder shed later. Cleaning might include:

- Washing

- Sanding

- Application of special chemicals to metal

In a few instances, special treatment is put on to improve sticking and prevent rust.

For wood and plastics, special treatments like plasma cleaning help make the surface coat-ready.

- Application

This is how one uses the powder. There are three major techniques:

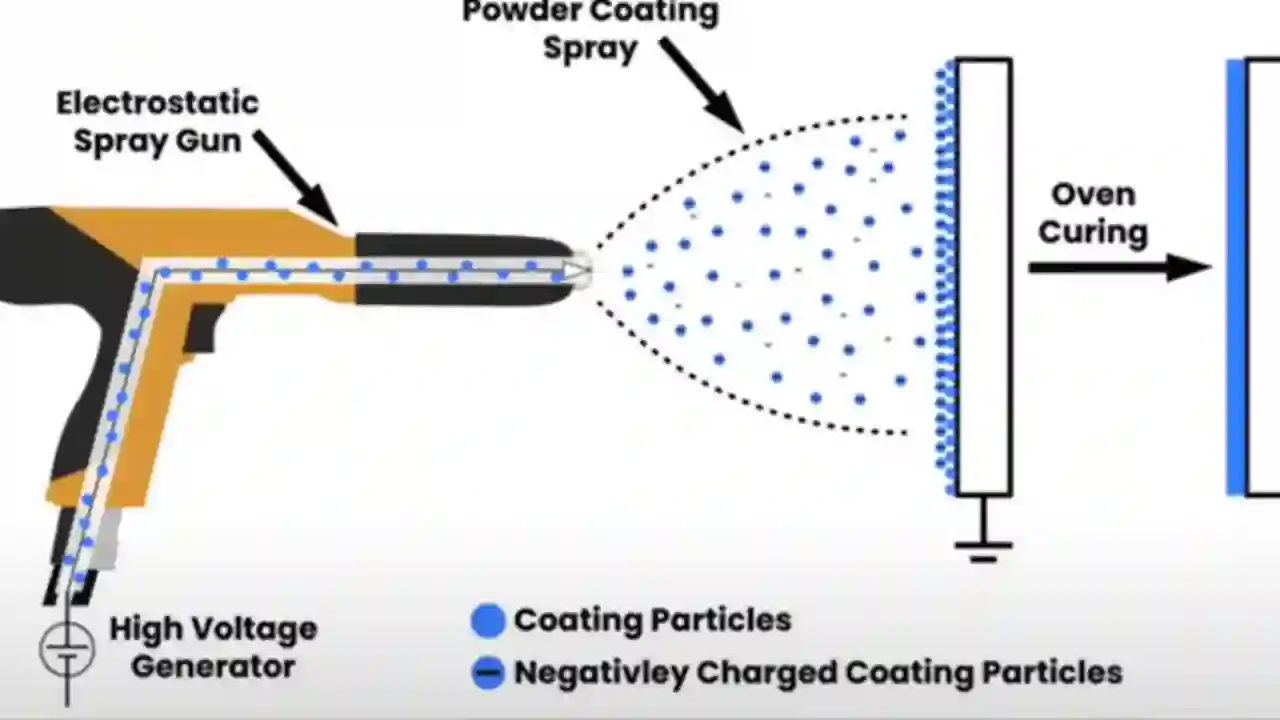

- a) Electrostatic Spray Gun (Corona Gun)

This is the most common technique.

The powder is sprayed from a gun and sticks to the object because of electricity.

- b) Fluidized Bed

A container of powder having air blown in to enable it to float such that it behaves like a liquid.

The hot object is put into the powder so it sticks.

- c) Electrostatic Magnetic Brush (EBM)

A new method for flat work pieces.

A roller applies the powder very thinly and uniformly

- Curing

The powder on the surface needs to be heated so that it melts and hardens.

Thermoset and Thermoplastic powders are heated in ovens (usually around 160°C–200°C).

UV powders use UV light and lower temperatures (about 110°C). They cure much faster – usually 1–2 minutes.

Powder Coating Guns – There are two generic spray guns:

- Corona Gun

Provides the powder with a negative charge

Object must be grounded (earthed) to collect the powder

May have problems like uneven coating or the “orange peel” texture when too much is applied.

- Tribo Gun

Deploys friction to transfer a positive charge to the powder.

Less problem with uneven coating

Needs special kinds of powder than the corona gun

Surface Preparation for Powder Coating

Clean surface preparation is necessary to obtain good adhesion, corrosion resistance, and good finish in powder coating. All types of contaminants in the form of dirt, grease, rust, or old paint must be cleaned before coating. The key steps are:

- Cleaning and Degreasing

The surface must first be cleaned to remove oil, grease, dirt, and other contaminants. This is typically done by:

Solvent Cleaning: Wipe or soak the parts in industrial solvents to erase grease and oils.

Alkaline Cleaning: Using alkaline-based cleaning solutions to break down and lift the impurities from the surface.

Detergent Washing: Sometimes used for less polluted surfaces.

- Rinsing

Then the parts are rinsed with water to remove any traces of chemicals or residue from the cleaning process. Multiple rinse stages can be used for thoroughness.

- Surface Preparation / Etching

For good adhesion, the surface must be slightly roughened. This is achieved by one of the following methods:

Mechanical Abrasion (Blasting):

Sandblasting or Grit Blasting: An abrasive medium is blasted onto the surface to remove rust, mill scale, or old coatings and to create a texture for the powder to adhere to.

It is highly effective on steel, aluminum, and most metals.

Chemical Etching (for aluminum or galvanized surfaces):

Acid-based solutions are used for the mild etching of the surface and to promote adhesion.

- Phosphating or Conversion Coating (Not Required but Recommended)

For corrosion resistance improvement and coating adhesion, a chemical conversion coating is typically applied. Some of the types are:

Iron Phosphate: Standard for general use.

Zinc Phosphate: Better corrosion resistance, for corrosive environments.

Chromate Conversion (for aluminum): Excellent corrosion resistance and adhesion.

- Final Rinse and Drying

After all treatment steps, parts are cleaned free of any rinsing (often with deionized water) and dried completely. Any presence of moisture will interfere with the powder application and curing process.

Drying: Typically done in a drying oven or through the use of compressed air to render the surface 100% dry before powder application.

Why Surface Preparation is Important

Without good surface preparation, powder coating will not adhere correctly, leading to peeling, bubbling, or poor durability. A surface that is clean, textured, and dry ensures a good bond and a durable finish.

Powder Coating Advantages

- Rust Protection

The powder coat is water- and air-repellent, and thus the metal cannot rust.

- Stronger Than Paint

Will not peel, crack, or scratch as fast as ordinary paint. Great for parts that get touched or moved a lot.

- Better Finish

No brush marks, no pinholes, and no bubbles like with ordinary paint.

- Renders Well

Comes in lots of colors and textures. You can make parts shiny, matte, smooth, or rough. You can even mix colours.

- No Toxic Chemicals

No rotten solvents or VOCs (Volatile Organic Compounds). It’s healthier for workers and the environment.

- Less Waste

Unused powder that will not adhere can typically be recycled.

- Fast Drying Time

The parts dry fast, especially with UV coating, which is cost- and time-saving.

Negatives of Powder Coating

- Heat Required

Most powders need heat to cure, so you cannot coat easily melted items unless using UV coating.

- Hard to Apply Thin Coats

Thin coats sometimes don’t look smooth and will have the orange peel effect.

- Expensive Equipment

Buying the spray guns, ovens, etc. can be pricey. Far more than painting and a brush.

Powder Coating Mistakes

- Not Cleaning the Surface

If the part is dirty or oily, the powder won’t stick well and will peel off later.

- Putting Too Much Powder

Too much powder can run or drip when heated, resulting in a bad finish.

- Incorrect Heat Settings

When the oven is hotter or colder than necessary, the powder will not cure correctly.

- Poor Grounding

If the part does not get a good ground, the powder will not adhere.

- Incorrect Powder for the Job

Various powders are designed for metal, plastic, outside use, inside use, etc. The wrong one will result in failure.

The Future of Powder Coating

Powder coating gets better with new technology:

- Greener Powders

Environmentally friendlier and safer for humans.

- Lower Temperature Curing

New powders use less heat so plastic and wood can even be coated.

- Faster Machines

New machines work faster and more accurately with less waste.

- Automatic Quality Checking

Computer and sensors will check the finish and fix problems automatically.

- More Styles and Colors

Soon we’ll see powder coating that looks like wood, marble, stone, or even chrome – all in one coat.

Can Powder Coating Be Done at Home?

Yes, powder coating can be done at home, but it needs special equipment like a

powder coating gun, a compressor, and an oven that can reach high temperatures

(at least 160°C or 320°F). Many DIY users buy small powder coating kits and use an old electric oven (used for something else, not food).

Note: Never use the same oven for food after powder coating. The chemicals can become toxic if combined with food. Always wear a mask and gloves when using powder.

Is Powder Coating Safe for the Environment?

Powder coating is far safer for the environment than standard paint. It has no harmful fumes, solvents, or VOCs (volatile organic compounds). The leftover powder (referred to as overspray) can be reclaimed and reused, so there is less waste.

Additionally, most new powders are designed to be non-toxic and recyclable, so they are even more environmentally friendly.

How Long Will Powder Coating Last?

Powder coating may last 15 to 20 years, sometimes longer. It will depend on:

- The material that is being coated

- The type of powder that is used

- How thoroughly the surface was clean before it was coated

- Where and how the item will be used (sun, rain, salt, scratches)

Products exposed to harsh weather or heavy use may degenerate earlier, but powder coating is far longer-lasting than paint in most applications.

Conclusion:

Powder coating is an efficient, long-lasting, and environmentally friendly finishing process with exceptional protection and appearance for numerous materials, most notably metals. Because of its resistance to corrosion, chipping, and fading, it is the preferred means of use in many industries.

Industrial, automotive, or residential, powder coating gives long-lasting performance and professional finish and as such is a good investment in both appearance and performance.

Suggested Posts

Polyurethane Top Coat Flaking or Peeling: Why It Happens

Holiday Detectors: A Detailed Guide