Holiday Detectors: In many industrial applications, the integrity of protective coatings is critical to prevent corrosion and damage to materials. A holiday detector is a machine specifically designed to identify “holidays” in these coatings. A holiday is any area of the coated surface that is unprotected or has a defect.

These defects can be very harmful to the material’s longevity and functionality, which is why it must be detected as early as possible. In this article, we will discuss holiday detectors, their uses, how they work, and give insight into the different types available in the market.

Here in this article we will also talk about voltage settings and calculations, pricing, and how and where these devices should be used.

What is a Holiday Detector Machine?

A holiday detector machine is equipment that detects the defects or “holidays” present on protective coatings applied to materials such as metals, concrete, and others. The purpose of this equipment is to detect regions where the coating applied is deficient or poorly coated. These areas can be eroded by atmospheric corrosion, which subsequently results in material strength reduction and a diminution in service life.

The holiday detector operates based on the passage of a controlled electrical current through the coated surface. If the coating is intact, no electrical current will leak through and the machine will show no defects. But in case of a gap in the coating, known as a holiday, the current will leak through the uncoated area and the machine will warn the user. Normally, a holiday will cause an audible or visual signal from the device.

What Are Holidays in Coating?

A holiday, within the context of coatings, would be referred to as a term that represents a flaw or imperfection of the protective coat. Generally, the term holiday defines a spot or area where a coating is partially missing, inadequate, or merely not applied adequately. These are usually caused by problems with the coating application process itself, an imperfectly spread or uneven coating substance, or sometimes by irregularities in the substrate.

The holiday is particularly a concern in the industries that have their protection mainly by the coating from environmental elements like moisture, chemicals, or extreme temperatures. In oil and gas, chemical processing, and pipeline construction industries, the protective coatings prevent corrosion. Even a tiny holiday may lead to critical problems because corrosion may start from the defect and propagate, eroding the integrity of the material.

These are detected by holiday detector machines. These allow correction, thus not being expensive and replaced later on. Holidays in coatings are specifically crucial for buildings subjected to a rough environment; hence, one of the more crucial structures such as bridges, tanks, pipelines, and offshore platforms.

Functions of a Holiday Detector

The main purpose of a holiday detector is to locate defects or holidays in coatings applied on materials. It does this by passing a voltage through the coating and monitoring for leakage in electricity. This leakage is caused when there is a defect in the form of missing coatings. Here are some of the main functions of a holiday detector:

Detection of coating defects: A holiday detector checks for areas under the protective covering that are deficient. It would ensure that the coverage is uniform in all areas such that no holes or imperfections exist that can compromise the strength of the protector.

Quality Control: Holiday detectors are very important in quality control, especially in manufacturing and construction environments. After applying a protective coating, a holiday detector ensures that the coating is applied correctly and without defects, guaranteeing that the material will remain protected.

Inspection : After Application of Coating: Holiday detectors are mainly utilized after the application of the coating process. When the coating dries, then the detector is used to check the surface and see if any areas have not been covered by the coating. This can be utilized for inspection wet or dry conditions, depending on the type of holiday detector.

Cost-Effective Preventative Measure: Holiday detectors help prevent costly damage to materials by detecting coating defects early. Detecting holidays before they lead to corrosion can save companies significant amounts of money in repairs and replacements.

Holiday Detectors-How Does Holiday Detector Work

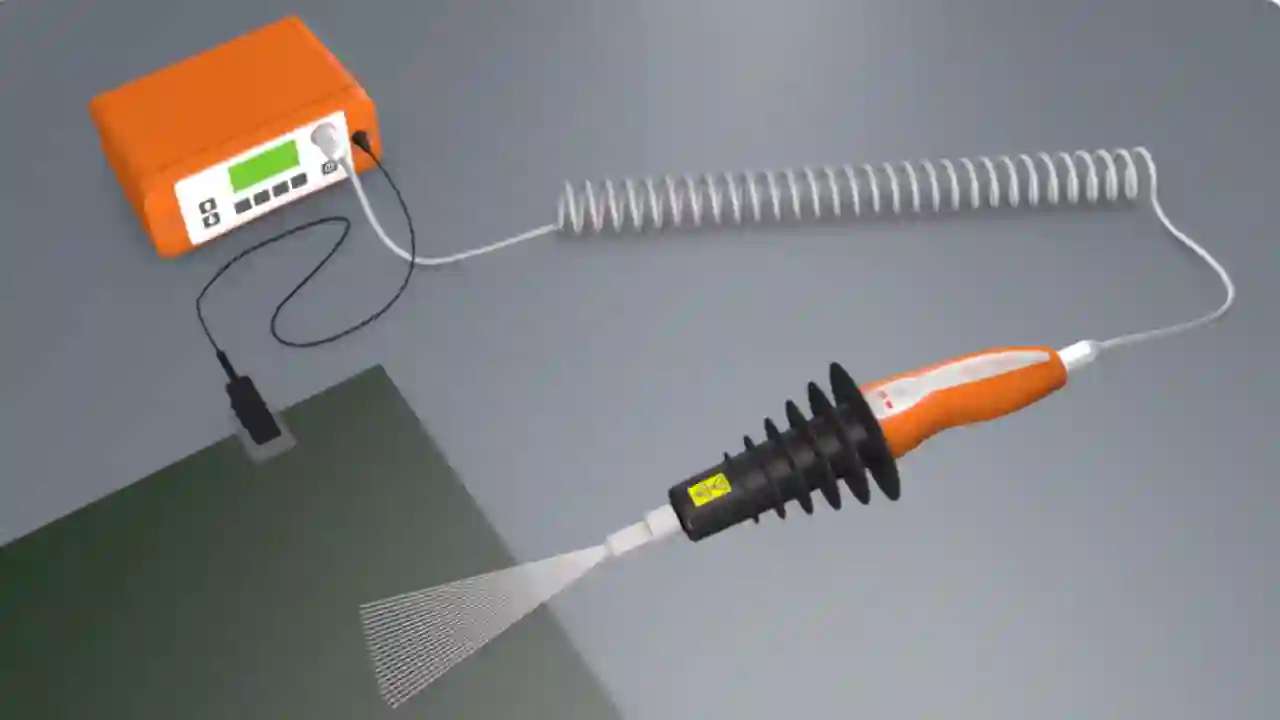

The holiday detector applies an electrical charge to the coated surface. The machine applies a voltage to the surface being inspected. In case the coating is complete, the electrical current will not pass through; however, in case of a defect, for instance, the absence of coating, the current passes through that particular spot and sounds an alarm that informs the operator about the holiday.

In most cases, the machine will give a visual or audible signal when it detects a holiday. This ensures that the operator knows of the defect and can take the necessary steps to correct it. Depending on the type of holiday detector, the voltage applied to the surface may vary, and the detection process can either be continuous or pulse-based.

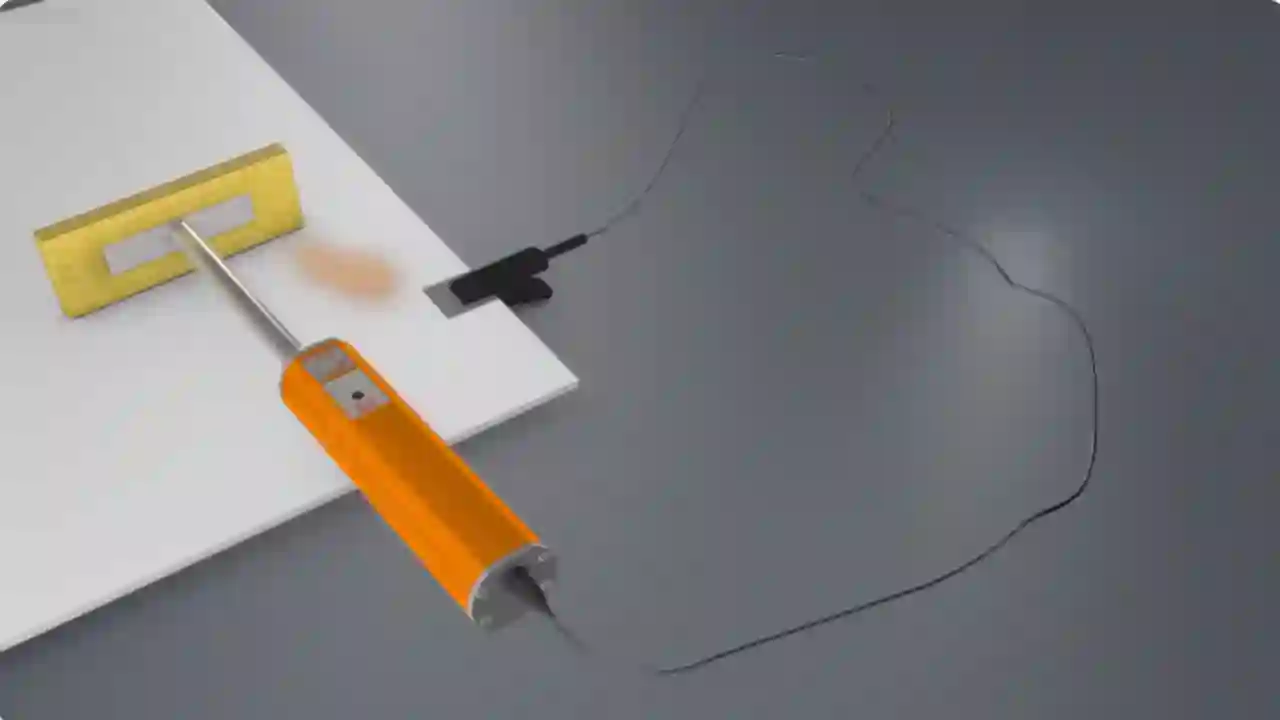

Low Voltage Holiday Detector

Voltage Setting and Computation

An essential requirement with the holiday detector is that a specific coating must set at a corresponding appropriate voltage related to its respective substrate. How high you adjust the voltage establishes how sensitive it would be with its setting on whether to highlight or reject such holiday findings so it wouldn’t detect errors which have already not happened and conversely it mustn’t skip them in general either.

Consider the coating thickness. Thick coatings usually call for higher voltage as it would take higher voltages for the detector to break through to look for the flaws. However, thinner coatings will require low voltage so as not to excite it too much as this would bring about a false alarm.

Consider the underlying substrate material– The material or substance that the layer is applied upon is also used to determine the precise voltage setting since some materials and substances may not be able to detect holidays due to low applied voltages but may be susceptible to higher values.

Use recommendations from the manufacture- The voltages are obtained from the same manufacturer who must have provided indications on the usage of the coats and the underlaying substances.

In most applications, the voltage would be set within a range of 5 kV to 20 kV. For instance, 0.1mm thickness may require around 5 kV, but a coating larger than 1mm may call for up to 20 kV. Certain holiday detectors feature variable settings wherein the operator has to adjust it according to requirements. For ready reference use this Holiday Detector Voltage Setting Calculator.

Types of Holiday Detectors Available in the Market

Holiday detectors have different types according to their use. The applications vary and come in a particular type that matches a certain type of industry and requirement. Examples of these holiday detectors are as follows:

Wet Sponge Holiday Detectors: This type of holiday detector uses a conductive sponge saturated in a solution to apply voltage across the coated surface. They are well suited for coatings on metal surfaces. The wet sponge method is widely used in industries where non-destructive testing is required and the electrical current is low, hence this type is safe to use.

High Voltage Holiday Detectors: These machines help in the detection of holidays in relatively thicker coatings such as those used in pipeline construction and other industrial applications. As high voltage detectors can deliver a considerable amount of electrical charge, they can detect defects in high-duty coatings. In industries that call for special levels of corrosion protection, these detectors are always necessary.

Pulse holiday detectors: These send out short electrical pulses instead of a continuous current. These are best used in the detection of small holidays or gaps in coatings that might be missed using other methods. Pulse detectors are sensitive to very fine defects in coatings; therefore, they are ideal for applications where accuracy is crucial.

Manual and automated holiday detectors: These come in both varieties. The operator must move the device over the surface to inspect the area using a manual model, whereas automated models may rely on robotics or other systems for scanning larger areas more quickly and efficiently.

Holiday Detector Machine Cost

The cost of a holiday detector machine can range from several hundreds to tens of thousands depending on the type and features of the device. Basic models costing between $100 and $300 will serve for lighter-duty applications and are useful for smaller projects with less demanding applications.

Advanced models offer high voltage capability, pulse detection, and scanning with an automation system. These cost anywhere from $500 to over $2,000. Those high-end models that can be used to scan large industrial surfaces or require precise detection may run much higher in price.

The needs of your project should be taken into account when buying a holiday detector. The price should reflect the type of coating, the required voltage range, and the scale of the inspection process. A less expensive model may be sufficient for smaller tasks, but more complex or large-scale projects might require a more sophisticated device.

Where and how should holiday detectors be applied? Holiday detectors can be used wherever coatings are used to prevent materials from corroding. Examples of industries using holiday detectors are

Oil and Gas: Pipelines and storage tanks are protected in the oil and gas industry against corrosion through applying protective coatings. Holiday detectors check for the correct application of the protective coating, free from any weakness in the coating layer.

Construction: In the construction industry, there is coating of steel beams and bridges, as well as other metal structures, in order to prevent rust and deterioration. Holiday detectors ensure that these coatings are properly laid and provide maximum protection.

Chemical Processing: Coatings are used in chemical plants for the prevention of corrosive chemicals from coming into contact with equipment. Holiday detectors inspect these coatings and ensure that they are quite effective.

Offshore Platforms: In the offshore industries such as oil exploration, the metals surfaces have to be protected from corrosion that occurs because of salt water. Holiday detectors are used on such platforms for complete coverage with the coating.

Holiday detectors are widely recommended for usage after application but before a put material comes to service. Routine use should take place within a coating operation that could have happened prior to corrosive exposure; that way holidays would be identified while still fresh without any subsequent potential damage caused through corrosion.

Conclusion

Holiday detectors are an important tool in industries where the integrity of coating is critical. They help detect holidays, thus preventing corrosion and extending the material’s life. Knowing the different types of holiday detectors, their working, and how to set the voltage appropriately can make a world of difference in the effectiveness of coating applications.

Suggested Posts

30 Oil and Gas Interview Questions and Answers for Mechanical Engineers

Industrial Surface Protection: Protecting Materials for Long-Term Use